Manufacturers today face increasing pressure to optimize speed, precision, and adaptability in their production processes. Robotic parts feeding solutions are stepping up as game-changers, reshaping how components are delivered and assembled on production lines. From reducing waste to accelerating workflows, these systems play a pivotal role in enhancing efficiency and driving profitability.

Let’s explore how robotic parts feeding solutions are transforming the efficiency and precision of manufacturing operations.

What Are Robotic Parts Feeding Solutions?

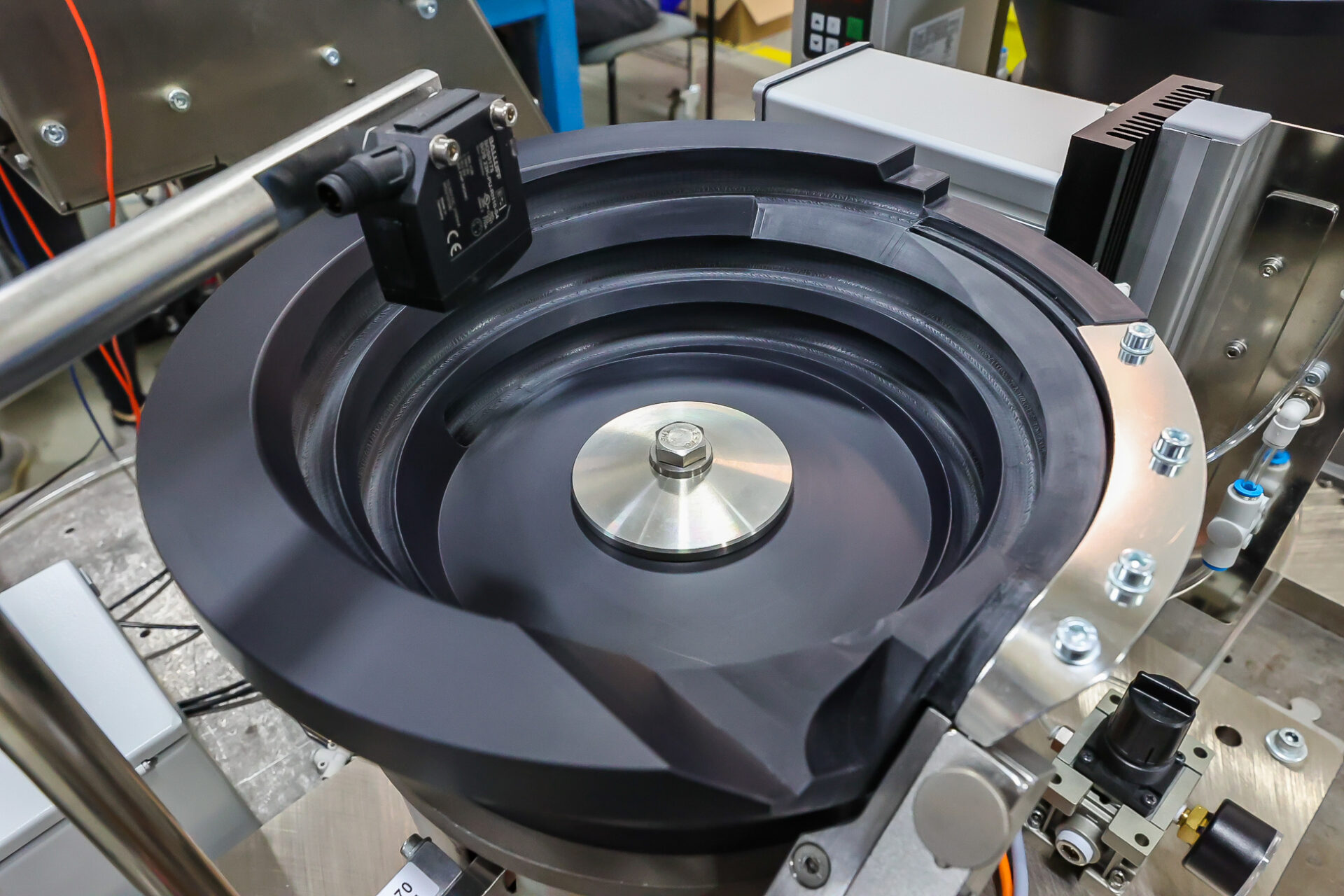

Robotic parts feeding solutions combine the strengths of traditional feeders such as Vibratory Bowl Feeders, Linear Feeders, and Conveyor based systems with advanced robotics to create a fully automated system. These systems not only sort, orient, and feed components with precision, but also bring flexibility and intelligence to the process, enabling them to adapt to various production requirements. They also allow direct load into the machine to remove excess part handling to reduce or eliminate micro-stoppages.

Key elements of robotic parts feeding systems include:

- Vibratory Bowl Feeders: A cornerstone of parts feeding, these feeders use controlled vibrations to position and orient parts for robotic pickup, ensuring smooth and efficient delivery.

- Linear Feeders: Designed for high output, linear feeders provide a steady flow of parts at high rates to keep production moving seamlessly.

- Conveyor Based Systems: Utilized for simple presentation with no risk of jamming to compensate for difficult parts or variation.

- Robotic Integration: By combining robotics with traditional feeders, these systems automate tasks like sorting, inspection, and precise placement, making them ideal for modern, high-speed manufacturing environments.

Robotic parts feeders elevate traditional feeding systems by adding automation, reducing the need for manual intervention, and enabling manufacturers to handle complex assembly processes with greater efficiency and accuracy.

The Efficiency Gains of Robotic Parts Feeding

Robotic parts feeding systems offer a range of benefits that significantly enhance manufacturing efficiency. By automating repetitive tasks, these systems ensure a continuous flow of components to assembly lines, eliminating bottlenecks, reducing downtime, and enabling manufacturers to meet tight deadlines with ease. Precision is another hallmark of robotic feeders, as they deliver components in the exact orientation required, reducing assembly errors and ensuring product consistency—a critical factor in industries such as pharmaceuticals and automotive manufacturing.

While the initial investment in robotic parts feeding systems may seem significant, the long-term cost savings are substantial. Automation reduces labor costs, minimizes material waste, and decreases the likelihood of costly rework due to errors. Additionally, these systems are designed with scalability in mind, allowing manufacturers to adapt to future growth. Whether scaling production or introducing new product lines, modern robotic feeders can handle changing demands without requiring extensive downtime or reinvestment. These benefits make robotic parts feeding systems a vital tool for any forward-thinking manufacturer.

Why Choose Robotic Feeders Over Traditional Methods?

Traditional parts feeding methods rely heavily on part geometry and consistent part quality to prevent stoppages. Robotic parts feeding systems eliminate these dependencies, offering a reliable and repeatable process that scales effortlessly.

For example, a vibratory feeder can handle thousands of parts per hour with perfect accuracy until a variation occurs in part quality or an external variation such as a foreign part or particulate. A robotic feeding system can simply ignore the variation ensuring that operations run like clockwork.

Unlocking New Possibilities with Automation

The beauty of robotic parts feeding solutions lies in their flexibility. Manufacturers across industries are leveraging these systems to achieve goals that were previously out of reach. Some common applications include:

- High-Precision Assembly: Ideal for industries like electronics and medical devices where precision is non-negotiable.

- Feeding parts traditional feeders have not been able to accomplish.

- Custom Solutions: Automated feeders can be tailored to handle unique parts or complex workflows.

- Changeover: Traditional systems may require physical tooling changeover to feed multiple variants while a robotic part feeding solution simply requires simple recipe selection through the HMI (Human Machine Interface).

Partnering with VTR to Drive Success

Implementing robotic parts feeding solutions requires expertise and customization. At VTR Feeder Solutions, we specialize in creating systems that align perfectly with your manufacturing goals. From vibratory feeders to linear feeders to fully automated robotic systems, our solutions are engineered to enhance your operational efficiency.

Our team works closely with you to understand your specific challenges and design a system that delivers measurable results. Whether you need to optimize an existing process or develop a new one from scratch, we’re here to help.

The Future of Manufacturing Efficiency

Robotic parts feeding systems are not just a trend—they’re the future of manufacturing. By investing in these technologies, manufacturers can improve efficiency, reduce costs, and remain competitive in an ever-changing market. Take the first step toward a more efficient production line today. Contact VTR Feeder Solutions to learn more about our cutting-edge robotic parts feeding systems and how they can transform your operations.