Products & Services

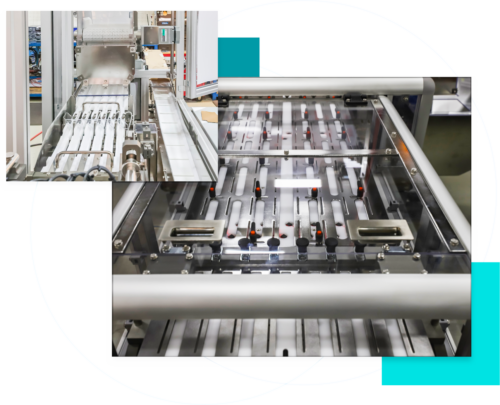

Linear Feeders

When high throughput is required with limited floor space, linear feeders are a great option compared to other types of feeders due to the compact design, operating as a single lane or with multiple lanes.

STRAIGHT LINE FEEDING

A compact, yet powerful system.

Linear Feeders take the concept of vibratory feeding technology into a straight line. Like our Machined Polyamide Bowls, these units are fully designed, machined, and simulated in-house to ensure repeatability and reduce footprint. Unique to our other feeders, the linear systems allow us to pick & choose any material for optimal feeding and allow them to be completely modular.

Get Started

Straight Line Feeding

Linear feeders utilize vibratory technology to guide parts into a straight line, ensuring each part is delivered in the correct orientation, within cycle time, for further processing. This is great for sorting & feeding complex components or systems that feed multiple part types.

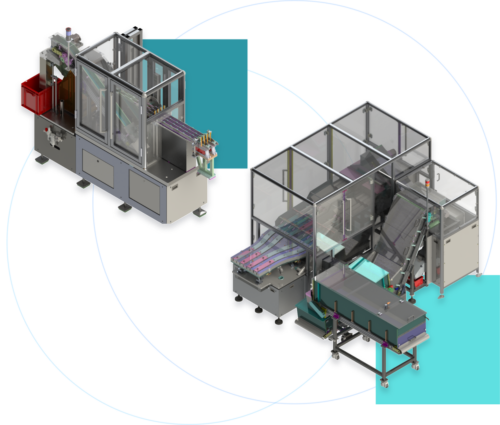

Modular Design

Our Linear systems allow us to pick and choose any material for optimal feeding and allow them to be completely modular. Once a single lane is proven during a POP (proof of principal) stage, we can replicate the exact same tooling across multiple lanes while still maintaining a compact footprint.

Cost Effective Solution

Equipped with Allen-Bradley controls, our Linear Feeders provide a cost-effective solution for multi-lane applications and complex, multi-variant parts. When change out tooling is required, our cartridges can simply be swapped with their appropriate set of rails.

Equipped With Digital Regulators

Our systems come equipped with digital flow meters and regulators (both lockable) with water separation units, removing the guess work from regular ball gauge flow meters. These units stay green when in range and change to red when over or under the set parameters, allowing for quick verification.

Flexible Hopper Styles

Our linear feeders are generally paired with a step feeder when an elevator hopper is too risky for storing parts and the need for gentler bulk storage is required. Both hopper styles are perfect for low load height requirements and provide quick purge features. We determine the best hopper style for your system during the design phase.

Integrated Return System

Our storage tracks can be vibratory, conveyor-based or pneumatic depending on your unique requirements. Each linear feeder comes complete with a return system for part recirculation and purge mode, reducing waste from your production. You can choose any type of escapement from the provided options for ease of integration.

Compact & Efficient

Maximize Space and Output

Linear Feeders are more compact than other types of feeders, making them suitable for use in tight spaces or on production lines with limited space. This compact size allows them to be easily integrated into existing production lines without requiring significant modifications or the addition of extra equipment.

In addition to their small size, Linear Feeders are also able to operate at high speeds, making them ideal for large volume production environments. This ability to work quickly allows them to keep up with the demands of modern production lines and helps to improve the overall efficiency and productivity of the manufacturing process.

Intricate Parts & Variations

One System, Multiple Parts

Linear Feeders can handle a wide range of parts, making them suitable for use in diverse production processes. This versatility allows them to be used in a variety of industries including medical device manufacturing, aerospace, and automotive.

Linear Feeders are designed to handle parts of different shapes, sizes, and materials. They can handle small, delicate parts as well as larger, more durable parts, making them suitable for use in a wide range of applications.

This ability to handle a diverse range of parts makes Linear Feeders an attractive choice for manufacturers who need to process a variety of different materials or who are looking for a single feeding solution that can be used across multiple production lines for low volume runners.

Minimize Downtime

Accurate & Reliable Parts Placement

Linear Feeders are highly accurate and reliable, ensuring parts are consistently orientated at the required cycle time. This helps minimize operational downtimes due to equipment failure. Accuracy is achieved using precise tolerances, high-quality components, and vigorous testing, to ensure parts are consistently presented in the correct orientation.

Another key advantage of linear feeders is their strong reliability. These feeders are designed to operate continuously for long periods of time and with minimal maintenance requirements. This means that manufacturers can rely on them to consistently deliver parts in the correct orientation and cycle time without the need for frequent repairs or downtime.

Ready to review how a Linear Feeder could help your production needs?

Our Linear Feeders use vibratory technology to feed parts through a production line in a timed, reliable, and repeatable fashion, with the ability to add multiple lanes as needed.

Request Quote