In today’s fast-paced manufacturing environments, efficiency and precision are critical. High-speed production lines rely on equipment that can keep up with demand while maintaining consistent quality. One essential component that helps manufacturers achieve this balance is the linear feeder.

Linear feeders play a vital role in ensuring parts are delivered quickly, smoothly, and precisely to the next step in the assembly or production process. They offer several advantages over traditional feeding systems, particularly in high-speed applications. Let’s explore some of the key benefits of linear feeders and why they’re indispensable in modern manufacturing.

Consistent Part Flow

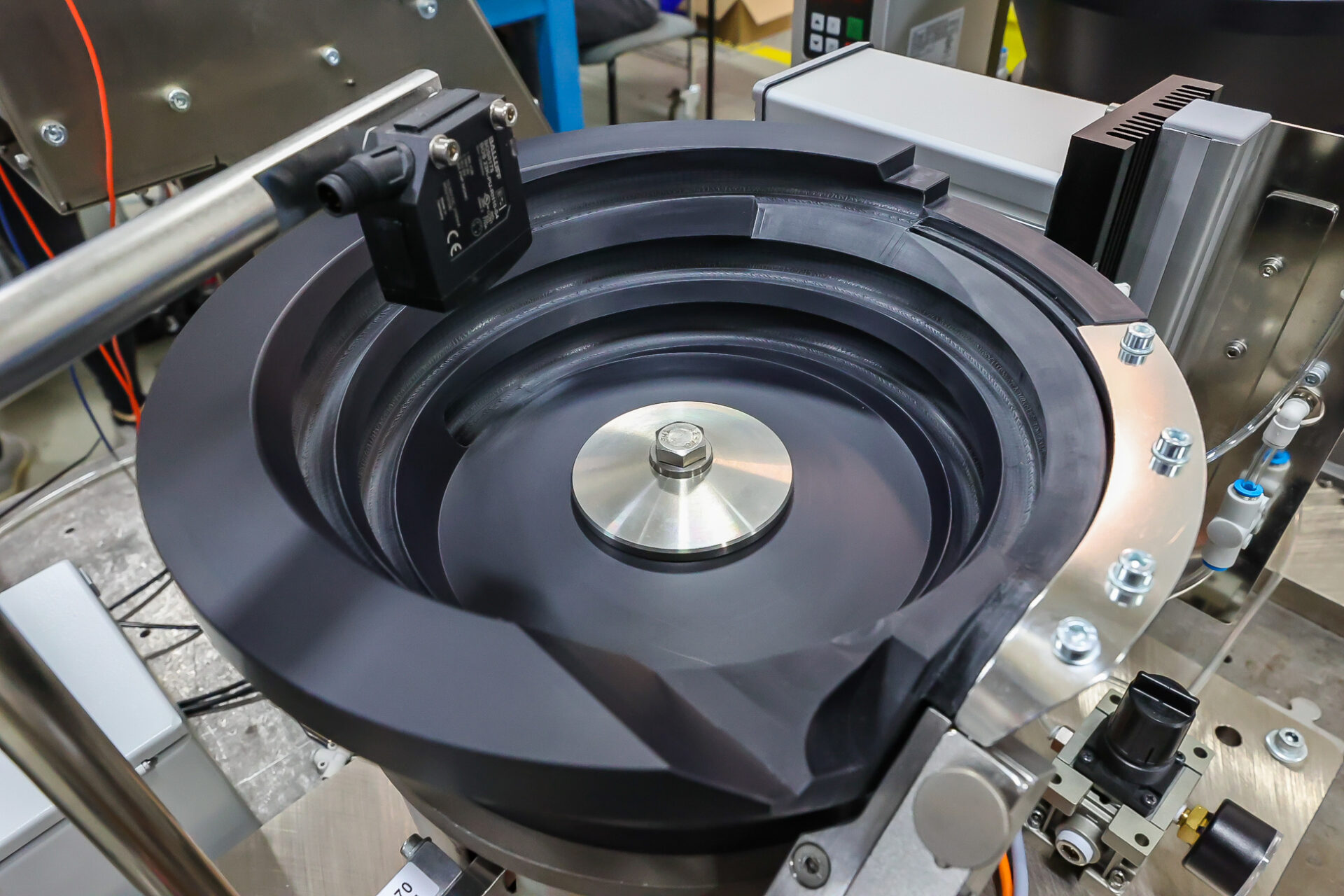

One of the primary advantages of linear feeders is their ability to deliver a smooth and controlled flow of parts. Unlike traditional bowl feeders, which rely on aggressive vibrations, linear feeders use a higher frequency drive unit to move parts along the production line more smoothly. This means parts arrive at their destination in a predictable, steady manner, minimizing jamming, noise, vibration transfer or misfeeds that could slow down the process.

For high-speed production, this consistency is crucial. When every second counts, having a feeder that provides a reliable flow of components without frequent stops or adjustments can make a significant difference in overall efficiency.

Precision in Handling Delicate Parts

Many industries, such as medical, pharmaceutical, and automotive, deal with small, delicate parts that require gentle handling. Linear feeders excel in these applications, offering more control over the movement of parts than hand fabricated systems. The ability to choose various materials and coatings prevent damage or separation of fragile components, ensuring the parts remain in the proper orientation as they move through the line.

This precision is especially important in high-speed production, where even the smallest deviation can cause a significant bottleneck or lead to faulty products.

High Throughput for Increased Productivity

Linear feeders are designed to handle high-speed operations without compromising on accuracy. They can move parts quickly and efficiently from one station to the next, ensuring that production lines run smoothly and without unnecessary delays. This high throughput capability directly contributes to increased productivity, allowing manufacturers to meet tight deadlines and fulfill large orders without sacrificing quality.

For industries where high-speed production is essential, linear feeders are a reliable solution to maintain output without compromising on precision. Multi-Lane systems guarantee 100% repeatable tooling with rigid support structures to prevent vibration transfer to the floor or adjacent cells.

Flexibility Across Industries

Another key advantage of linear feeders is their adaptability across various industries and applications. Whether you’re in automotive manufacturing, medical device production, or another industry, linear feeders can be customized to fit the specific needs of your process. Their flexibility in handling different shapes, sizes, and materials makes them ideal for a wide range of production lines, from assembling electronic components to handling packaged goods.

In high-speed environments, this versatility is essential. Manufacturers need equipment that can adjust to different part requirements without requiring frequent modifications or manual intervention. Linear feeders provide that flexibility, making them a valuable asset in diverse production settings.

Reduced Downtime and Maintenance

In addition to their operational benefits, linear feeders also offer advantages in terms of maintenance. Their straightforward design typically requires less upkeep than hand fabricated bowl feeding systems, leading to reduced downtime for repairs or adjustments. For high-speed production lines, where downtime can lead to significant losses in both time and revenue, this reliability is a major advantage.

The need for grinding, welding and specialized technicians is a day of the past. Simply swap out the tooling cartridge with a few bolts, and restart the cycle. Our systems are machined to tolerance and designed for exact repeatability.

By minimizing maintenance needs and reducing the risk of system failures, linear feeders contribute to smoother, more efficient production workflows.

Conclusion

Linear feeders are an essential component in modern high-speed production environments, offering precision, consistency, and flexibility. They provide a reliable solution for delivering parts efficiently, helping manufacturers improve productivity and reduce downtime. For industries that depend on high-speed output and quality control, the advantages of linear feeders make them an ideal choice for maintaining performance without compromising on accuracy.

As the demands of the manufacturing world continue to evolve, linear feeders remain a trusted tool for keeping production lines moving swiftly and smoothly, without the need of specialized technicians.

As a global leader in linear feeder manufacturing, VTR Feeder Solutions is here to help you optimize your production. Explore our in-depth page on linear feeders or reach out to our team to discuss a solution tailored to your unique operational needs.