Products & Services

Vibratory Bowl Feeders

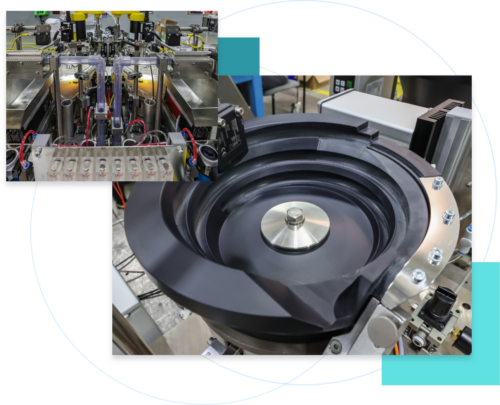

As North America's leading manufacturer, VTR's bowl feeders are an ideal choice for applications that require accurate material accountability and consistent repeatability. Our vibratory bowl feeders are designed with a calmer drive unit, which ensures they operate quietly and with minimal vibration, making them suitable for use with a variety of parts.

100% REPEATABILITY

Designed with material accountability and exact repeatability in mind.

Designed with 3D SolidWorks software and machined on a 5-Axis Trunnion CNC Mill, VTR offers machined bowl feeders equipped with a lifetime warranty. Our bowls are manufactured entirely by machines, allowing these units to be 100% repeatable. They are available in white or blue with FDA certification or black for automotive applications.

Get Started

Lifetime Guarantee

VTR's machined bowls remove variability found in hand-crafted feeder art, and come with a lifetime warranty. If the bowls fail under normal operation, VTR will replace them free of charge within days.

100% Repeatability

VTR's systems are fully designed using 3D SolidWorks software and are machined using a 5 Axis Trunnion CNC Mill. If a replacement bowl is required, our customers can simply swap the counterpart bowl by loosening a center bolt and re-installing the new bowl on dowels, without the need for a service technician.

Less Vibration

VTR's bowls use a calmer drive unit to help parts travel smoothly through the orientation features. With a higher frequency drive unit, there is no aggressive vibration transfer. Our bowls also have a smaller footprint compared to traditional hand-fabricated bowls.

PROCESS INTRICATE PARTS

Spring Detangler Available

Our machined bowls can have an integrated Spring Detangler that is specifically designed to feed springs more effectively. Spring feeder systems often struggle with tangling or jamming. VTR’s Spring Detanglers solve these issues by separating the springs and reintroducing them into the system without a large recirculation system. This helps ensure that the springs are untangled consistently, without causing jams or disruptions to the overall cycle time. The Spring Detangler is integrated into the bowl feeder itself, allowing for seamless integration into the overall system without any additional setup or maintenance. This feature can help improve the efficiency and reliability of the feeder system and ensures that springs travel into the storage track untangled and ready for processing. Our systems come with an ejection system for difficult springs.

Hoppers, Colours & Controls

Multiple Styles Available

VTR’s bowls have been designed to be flexible and can be integrated with a variety of different hopper types and accumulation devices. This allows us to tailor the feeder system to our customers’ specific needs and requirements. The different hopper types that can be used with VTR’s bowls include elevator hoppers, stepper hoppers, live bottom systems, and vibratory hoppers. Each of these hoppers has its own unique features and benefits, and selecting the appropriate hopper will depend on the specific application and the parts being fed.

In terms of accumulation devices, VTR’s bowls can be integrated with various types such as vibratory, pneumatic or conveyor based. These devices are used to collect and store parts that are fed from the bowl before they are released into the next stage of the manufacturing process. The accumulation device chosen will depend on the specific application, the parts being fed, and the desired level of automation.

VTR’s bowls are also available in different colors including black for the automotive, while white or blue, for consumer, medical or pharmaceutical. In addition, the bowls can be fitted with a control panel for a turn-key solution, which is especially useful for multilane applications and more intricate part handling. This makes it easy to quickly integrate your new system into the facility and start using it immediately.

High Accuracy & Repeatability

Escapement Options

VTR offers a variety of escapement options to take parts from storage, which are used to release parts from the feeder system in a controlled and precise manner. These options include cross shuttles, strip forward escapements, linear actuators, finger releases, placement spears, blow feed systems and rotary indexers. Each of these options has its own unique features and benefits, and selecting the appropriate one will depend on the specific application and the parts being fed.

Cross shuttles are a great option for pitch requirements. Depending on the part size, multi-pocket cross shuttles can be supplied for custom applications. With the use of a simple cylinder, the parts are released in a controlled and orientated manner.

Finger releases can be used separately or integrated with any style of escapement. The finger release system uses one or more cylinders to control the parts through the flow of the storage track, especially when parts can shingle or are flexible.

Placement spears escapement devices use a spear-like mechanism to release parts from the feeder system. The placement spear is positioned at the end of the feeder system, and employs a basic mechanical movement to discharge parts from the bowl in a controlled fashion.

Rotary indexers use a rotating cylinder or indexer to release parts from the feeder system. The rotary indexer is placed at the end of the feeder system and can use pneumatics or electrics for delivering parts to a machine. These can be designed with unique pitch requirements and for higher speed applications.

All of these escapement options have the ability to release parts with high accuracy and repeatability and can be integrated with our feeders.

FAQs: Everything You Need to Know

-

A vibratory bowl feeder is a type of automated parts feeder that uses controlled vibration to move, orient, and deliver parts in a specific orientation. The bowl itself sits on top of an electromagnetic drive unit, which generates precise vibrations that move parts up a spiral track along the inner wall of the bowl. As parts travel along the track, they encounter tooling features that manipulate parts into the desired orientation, reject improperly oriented parts and allow only correctly aligned parts to pass through. These systems are widely used in automated parts handling and assembly processes, where consistent part presentation is critical to downstream automation or robotic pick-and-place operations.

-

Polyamide bowl feeders are fully designed in CAD and CNC-machined from solid blocks of engineering-grade material. They offer significant technical and operational advantages over traditional hand-fabricated metal bowls. The most important of these is precision. Because polyamide bowls are machined directly from CAD models, there is 100% repeatability between systems. This means if you need a replacement bowl down the line or if you’re deploying feeders across multiple production lines, you can count on each system behaving exactly the same. There’s no variability, no need for retraining robots or vision systems, and minimal downtime when swapping out equipment.

In contrast, traditional metal bowl feeders are typically handcrafted and welded, which introduces variability from one feeder to another. Even small differences in the track height, angle, or tooling position can cause misfeeds, inconsistent part orientation, or increased tuning time, especially when using robotic pickers or vision-guided automation. Hand-built bowls are also more susceptible to weld fatigue and can be difficult to replicate for scale production.

Beyond precision and consistency, polyamide bowls are quieter in operation, chemically inert and non-porous. These properties make them ideal for cleanroom environments and industries with strict hygiene standards, such as pharmaceutical, food processing, and medical device manufacturing. When uptime, scalability, precision and consistency matter, especially in high-speed or regulated applications, a machined polyamide vibratory bowl feeder is the clear choice.

-

Vibratory bowl feeders are ideal for applications where high-speed, reliable orientation of uniform parts is required. If your parts are consistent in size and shape, and must be fed into downstream processes, such as robotic handling, assembly stations, or packaging equipment, a vibratory feeder may be the most efficient solution. Key considerations include part geometry, material, required feed rate (typically measured in parts per minute), cleanliness requirements, and the available footprint on your production line. For more complex applications involving high part variability or lower-volume production, alternative systems like flex feeders or robotic bin picking may be more appropriate. At VTR, we offer application reviews to help determine the best parts feeder for your needs.

-

As a leading vibratory bowl feeder manufacturer, VTR Feeder Solutions focuses on precision engineering and long-term performance. Our vibratory bowl feeders are manufactured using high-precision CNC machining, which allows them to be created exactly the same every time based on a digital design. This results in 100% repeatability, meaning if you need to replace a bowl or install multiple systems across different lines or facilities, each one will perform identically. There’s no variation from one bowl to the next, which reduces setup time, eliminates reprogramming for robotics or vision systems, and minimizes downtime during replacement.

Our team is known for tackling difficult parts that others can’t feed. We also offer full integration with automation systems, including robotics, sensors, inline vision, and PLC controls. Our vibratory feeders are built for 24/7 industrial use.

-

Yes, and in fact, VTR specializes in building vibratory feeders for cleanroom, medical, and pharmaceutical applications. Polyamide bowl feeders are especially suitable for these environments due to their non-porous and chemically resistant properties. They are easy to clean, do not absorb contaminants, and maintain a smooth finish that resists buildup. Our feeders can also be constructed with stainless steel components, FDA-compliant coatings, and washdown-rated enclosures if required. These features ensure compliance with GMP, ISO 13485, and other regulatory standards.

-

Vibratory bowl feeders are designed to handle a broad range of part materials, including plastics, elastomers (rubber or silicone), aluminum, stainless steel, brass, and various engineered composites. Each feeder is custom-built to match the physical and functional characteristics of the part being handled. Key considerations include the part’s weight, surface texture, material hardness, electrostatic behavior, and sensitivity to impact.

No matter the material, the design of the feeder and tooling is always tailored to ensure smooth, efficient, and consistent movement of parts through the system. This adaptability is a key reason vibratory feeders are the go-to solution for automated parts handling across so many industries.

-

Feed rate depends on a number of variables, including part size, orientation complexity, and track design. Most vibratory feeders operate in the range of 30 to 120 parts per minute. For simple, lightweight parts with minimal orientation requirements, rates of 200 PPM or higher can be achieved. The key to high-speed performance is a combination of well-tuned drive systems and precisely machined tooling. At VTR, we optimize every feeder for your required throughput while maintaining reliability and orientation accuracy.

-

Several factors can lead to degraded performance in vibratory feeders. These include wear on the internal tooling, contamination or buildup inside the bowl, fatigue of drive springs, improper cleaning, and cracked welds (especially in older hand-fabricated metal bowls). Vibration tuning may also drift over time, especially if the controller is not calibrated or the load on the feeder changes. One of the key advantages of VTR’s polyamide bowl feeders is their long-term durability, machined from a single piece of material, they resist deformation and require significantly less maintenance than welded systems. We also provide support and service options to ensure your feeders perform consistently over time.

-

Vibratory bowl feeders do produce some noise as parts move and vibrate through the bowl, especially when feeding metal components at high speeds. However, noise levels can be minimized through smart design and material choice.

Polyamide bowl feeders are naturally quieter than traditional metal bowls due to their smooth, machined surface and impact-dampening properties. For applications in medical, pharmaceutical, or cleanroom environments, VTR recommends polyamide for both its quieter operation and hygienic benefits.

To further reduce noise, VTR can integrate acoustic enclosures, vibration isolation, and low-amplitude tuning. These options are especially useful when feeders are installed near operators or in quiet production environments.

-

Yes, our vibratory feeder systems are designed with integration in mind. We regularly supply feeders for use in robotic pick-and-place cells, automated assembly lines, packaging systems, and vision-inspection stations. Our team provides full mechanical, electrical, and software integration, including sensors, actuators, PLC programming, and HMI interfaces. Whether you’re working with Fanuc, ABB, or other automation platforms, our systems are built to plug into your existing production infrastructure with minimal downtime. The VTR team works closely with our customers to ensure a seamless integration with their equipment.

-

To provide an accurate and detailed quotation, we’ll need some key information about your part and application. The most important items include:

- Part samples or CAD files

- Desired feed rate (parts per minute)

- Required part orientation

- Details about the next process (robot pick-up, assembly, inspection, etc.)

- Any cleanliness, material, or environmental requirements (e.g., cleanroom, washdown, static sensitivity)

- Information about available space, height, and integration constraints

- Requested Storage Capacity

This information allows our team to assess feasibility, determine the right feeder type, and design a custom system that fits seamlessly into your production environment.

You can submit your details through our official quote request form here. Once submitted, a member of our team will follow up promptly to review your application and discuss next steps.

Precision Feeding Starts Here

As North America's leading manufacturer, VTR offers a lifetime warranty and 100% repeatability on our bowl feeders. With many escapement options, and a spring detangler available, we are confident we can deliver a vibratory bowl feeder that works best for your operations.

Request Quote