Products & Services

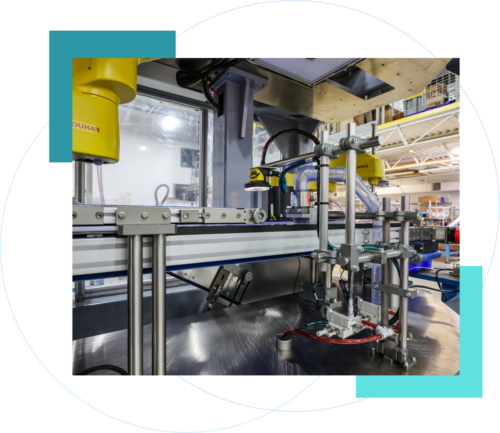

Robotic and Hybrid Flex Feeders

Reduce operating costs & risks with our innovative Flex Feeders. These systems are great for complex geometry and multi-part variations without the need for mechanical changeover.

POWERED BY ROBOTICS

A powerful system customized to you.

What happens when you combine modern technology, the highest quality components and an experienced team of programmers and designers? You get the most powerful parts feeder on the market. We leverage our knowledge, experience and technology to build a system for your unique operations in the medical, pharmaceutical, ready-to-eat foods, and automotive industries.

Get Started

Robotic Technology

Our Robotic & Hybrid Systems rely on vision-guided technology and our customized Flex Feeder to maximize the pickable parts, using a robotic arm to pick each part accurately & efficiently. Robotic technology makes picking & sorting incredibly efficient and accurate, reducing operating costs & risks. We are an Authorized Fanuc System Integrator (ASI) but also specialize in Epson, ABB, Staubli and KUKA. We have programmed other robotic platforms to suit individual company needs.

One Feeder, Multiple Parts

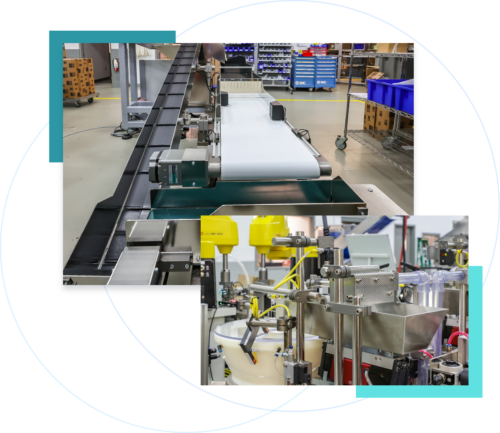

One of the biggest advantages of our Robotic and Hybrid Feeder systems is their ability to feed multiple part types in a single system without the need for mechanical changeover. This ensures your production is efficient, reduces downtime and maximizes productivity. Simply empty the system with the auto-purge features and select the part recipe to initiate product changeover, creating an operator friendly application.

Jam Free & Recirculation

Our systems have been rigorously developed and tested to eliminate jams. They are equipped with a return system to catch and recirculate unpicked parts. These features increase productivity and reduce waste, saving customers money and maximizing output.

REDUCE COSTS & RISKS

Precision Meets Convenience

Our vision guided Flex Feeders are typically used when numerous part types or variations need to be fed in one system with no changeover. These systems help reduce costs, operator intervention & risks on more intricate parts even though a machined feeder can be provided. VTR pre-orientates the parts prior to the vision system, to increase the number of pickable parts. The parts are then picked by a robot via static pick or belt tracking and loaded directly into your system. Our systems run jam free with a return system for recirculation for parts that are unpicked. Bulk storage is provided for increased walk away time, especially during lights out applications.

FANUC ASI

Industry Leading Technology

VTR is a FANUC ASI that provides unparalleled, robust, and long-term equipment complete with support using Scaras, 6-Axis, Deltas, and every robot in between. Our systems undergo strenuous testing to ensure the maximum pickable parts go into a defined field of view with no downtime, utilizing Fanuc expertise. These systems allow us to load directly into your machine with consistent accuracy and limited maintenance. Our vast knowledge of robot programming allows us to partner with ABB as well and have great experience integrating Epson, KUKA and Staubli.

FAQs: How Can Robots Feed Multiple Parts in the same Feeder?

-

A Flex Feeder is an automated part-feeding system that is capable of feeding a variety of components with different shapes, sizes, and orientations. It’s a flexible and adaptable solution that allows quick changeovers between different parts without the need for extensive mechanical retooling. Flex Feeders can also be a good solution for feeding components that lack the required physical attributes for traditional feeding technologies.

The system typically consists of a bulk storage hopper, a means of part presentation, a vision system, a return to bulk system, and a robot to pick and place the parts correctly.

VTR offers several different styles of Flex Feeders, the final solution of which is determined by a number of factors including:

- Number of part variations to be fed

- Size of parts to be fed

- Physical features of parts to be fed

- Overall feed rate of the system

- Type of equipment the parts are feeding into

-

A robot can be used in feeding systems to separate, orient, pick and place parts. Robotic Flex Feeders rely on a vision-guided platform. They can identify, pick and place parts dynamically, rather than through fixed mechanical tooling. Feeders using robots can often deliver a gentler solution to part picking than other tooling methods.

The End of Arm Tooling can often be designed to pick multiple variations of parts. When this is not the case, it can be designed to be either manually or automatically changed out based on part families. This flexibility allows manufacturers to feed multiple part types on one system, accommodate frequent changeovers, and handle delicate or irregularly shaped components that can be difficult to manage with traditional feeding technology. By combining robotics, vision, and intelligent part handling, Flex Feeders offer a dynamic solution to feeding multiple part types in one footprint.

-

A Robotic Flex Feeder uses a combination of pre-orienting and singulating features, machine vision, and robotics to deliver parts efficiently and accurately. Parts are distributed within a field of view, and imaged by a vision camera. The vision system identifies the position and orientation of each part in real time, while the robot picks only those that are correctly oriented and places them into the next process.

Any parts that aren’t ready for picking are automatically re-circulated and re-presented by the feeder system until they can be identified and picked. This continuous loop enables steady, consistent feeding without manual intervention. Fixed tooling is either not required or designed to be quick change cartridges. This ensures changeovers are as simple as loading a new part recipe, making robotic flex feeders ideal for high-mix and rapidly changing production environments. The flexibility allows for automation of low production runs that would otherwise be too costly for dedicated feeding equipment.

-

Robotic Flex Feeders can offer exceptional flexibility, especially for manufacturers running multiple part styles or frequent product changeovers. Instead of relying on dedicated mechanical tooling, these systems use vision-guided robotics to identify, orient, and deliver parts on demand. This reduces setup time, minimizes physical tooling, and keeps production lines moving when parts or models change. The result is a highly adaptable feeding process that supports mixed-part production environments, short product lifecycles, and modern flexible manufacturing strategies, all while improving consistency, uptime, and overall efficiency.

-

Robotic Flex Feeders are ideal for industries that demand precision, traceability, and efficient handling of multiple component variations. They’re especially valuable in regulated and high-performance sectors where product quality and reliability are non- negotiable, including:

- Medical Device Manufacturing – precise handling of small, delicate, and sterile-critical components such as surgical instrument parts, diagnostic housings, implant components, and micro-assemblies. Vision-guided robotic feeding ensures accuracy, cleanliness, and repeatability, which is essential for FDA and ISO- regulated production environments.

- Pharmaceutical Production & Assembly – automated orientation and delivery of vial stoppers, syringe parts, vial caps, dosage-control components, and other drug delivery elements. Robotic feeding supports efficient manufacturing workflows, traceability, and consistent performance in tightly regulated environments.

- Automotive Manufacturing – efficient feeding of clips, fasteners, plastic and metal fittings, electrical connectors, sensors, fuel-system components, and seals. Robotics-driven feeding supports continuous production, part variation, and the high consistency required for advanced vehicle platforms and electric battery systems.

- Packaging Automation – precision feeding of closures, bottle caps, fitments, applicators, blister components, tray inserts, placing parts in cartons, and packaging and bagging components. Ideal for operations requiring speed, consistency, and quick changeovers across formats.

- Consumer Packaged Goods (CPG) – flexible feeding for caps, lids, pumps, nozzles, closures, dispensers, and molded plastic components across personal care, household, and retail product categories. This is ideal for companies that frequently introduce new SKUs.

- Food & Beverage Packaging – consistent feeding of caps, fitments, closures, dispensing components, and sanitary-contact parts used in food and beverage filling and packaging lines. Supports hygienic design requirements and rapid changeovers.

- Electronics & Sensor Assembly — precise handling of miniature components and delicate PCB-related parts

- General Industrial & Contract Manufacturing — enabling flexible feeding for multi product assembly lines and evolving production requirements

Whether your operation focuses on high-precision micro-assembly or packaging automation across multiple SKUs, robotic feeding systems deliver the flexibility, consistency, and uptime needed in today’s dynamic manufacturing landscape.

-

Robotic feeding systems streamline production by removing the need for manual sorting, part handling, and mechanical retooling between product runs. Vision-guided picking ensures every part is accurately detected and oriented, reducing jams, misfeeds, and scrap. With continuous part flow and automated changeovers, manufacturers gain higher throughput, improved consistency, and far less downtime, all while lowering labor requirements and overall operating costs.

-

Robotic Flex Feeders are designed to handle a broad range of components, including caps, housings, electrical connectors, fasteners, molded plastic parts, stamped metal components, and other precision-manufactured pieces. While they can be engineered for many shapes and materials, they perform best when feeding parts under 5 inches/150mm in size and typically below a few hundred grams in weight.

This size and weight range ensures optimal performance because:

- Vision recognition is more reliable when parts fit cleanly within the camera’s field of view

- Vibration and re-circulation are more efficient, making it easier to present and re- orient parts quickly

- Robotic pick-and-place cycles are faster when the robot handles smaller, lighter parts

- End-of-arm tooling doesn’t need excessive force, improving speed, accuracy, and repeatability

- Part stability and flow are maintained, reducing the chance of tipping, rolling, or collision

- Feeders stay compact, which lowers footprint and integration cost

Most applications in medical devices, pharmaceuticals, automotive components, and consumer/packaging products fall naturally within this range, making robotic flex feeding an excellent fit for high-precision and high-mix production in these industries.

For components outside this typical envelope, VTR engineers custom solutions, combining robotics, conveyors, intelligent bulk hoppers, and specialty part-presentation methods to reliably feed larger or heavier items when the application requires it.

-

Flex Feeders are designed for adaptability. With minor vision adjustments and robot reprogramming, a Flex feeding system can feed completely different parts. This makes them ideal for manufacturers pursuing lean or modular production strategies where product variants change often.

-

Unlike traditional vibratory bowl and linear feeders, which are optimized for single-part, high-volume applications, robotic flex feeders add the advantage of fast digital changeovers and the ability to handle multiple part types on the same system. This makes them ideal for modern, flexible manufacturing environments where product variation and adaptability matter.

-

Yes. Every VTR robotic feeder is engineered to meet the specific requirements of your parts, materials, and production line. Our engineering team conduct part analysis, simulation, and prototyping to ensure reliable orientation and feed rates before full system integration.

-

Robotic parts feeders are designed for minimal maintenance. Routine cleaning, calibration checks, and periodic inspections of moving components ensure reliable performance. VTR provides service and support packages tailored to your system.

-

Absolutely. VTR provides complete turnkey integration, including design, build, installation, robot programming, and on-site commissioning. We also train your team to operate and maintain the system confidently.

Our Most Powerful System Yet.

Our Robotic Flex Feeders are our most modern, flexible system yet, with the ability to feed multiple intricate parts in a single system without the need for mechanical changeover. Our industry-leading technology will make your operations more efficient & reliable, exceeding all of your expectations.

Request Quote