Products & Services

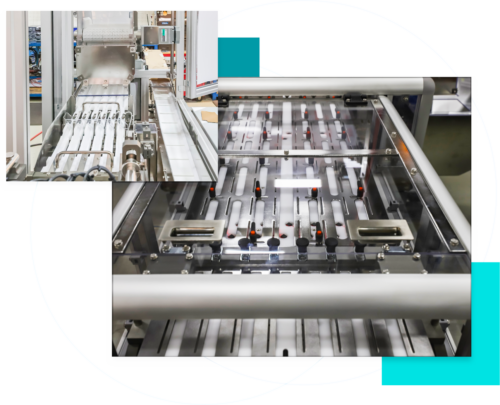

Linear Feeders

When high throughput is required with limited floor space, linear feeders are a great option compared to other types of feeders due to the compact design, operating as a single lane or with multiple lanes.

STRAIGHT LINE FEEDING

A compact, yet powerful system.

Linear Feeders take the concept of vibratory feeding technology into a straight line. Like our Machined Polyamide Bowls, these units are fully designed, machined, and simulated in-house to ensure repeatability and reduce footprint. Unique to our other feeders, the linear systems allow us to pick & choose any material for optimal feeding and allow them to be completely modular.

Get Started

Straight Line Feeding

Linear feeders utilize vibratory technology to guide parts into a straight line, ensuring each part is delivered in the correct orientation, within cycle time, for further processing. This is great for sorting & feeding complex components or systems that feed multiple part types.

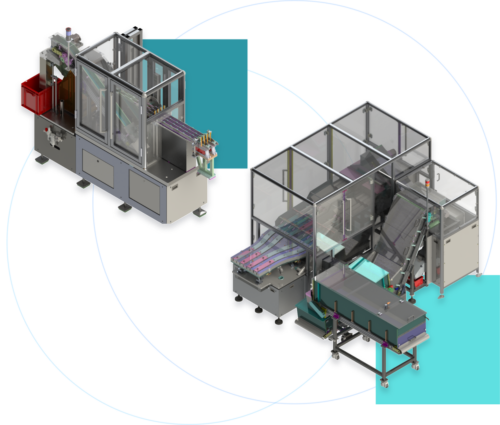

Modular Design

Our Linear systems allow us to pick and choose any material for optimal feeding and allow them to be completely modular. Once a single lane is proven during a POP (proof of principal) stage, we can replicate the exact same tooling across multiple lanes while still maintaining a compact footprint.

Cost Effective Solution

Equipped with Allen-Bradley controls, our Linear Feeders provide a cost-effective solution for multi-lane applications and complex, multi-variant parts. When change out tooling is required, our cartridges can simply be swapped with their appropriate set of rails.

Equipped With Digital Regulators

Our systems come equipped with digital flow meters and regulators (both lockable) with water separation units, removing the guess work from regular ball gauge flow meters. These units stay green when in range and change to red when over or under the set parameters, allowing for quick verification.

Flexible Hopper Styles

Our linear feeders are generally paired with a step feeder when an elevator hopper is too risky for storing parts and the need for gentler bulk storage is required. Both hopper styles are perfect for low load height requirements and provide quick purge features. We determine the best hopper style for your system during the design phase.

Integrated Return System

Our storage tracks can be vibratory, conveyor-based or pneumatic depending on your unique requirements. Each linear feeder comes complete with a return system for part recirculation and purge mode, reducing waste from your production. You can choose any type of escapement from the provided options for ease of integration.

Compact & Efficient

Maximize Space and Output

Linear Feeders are more compact than other types of feeders, making them suitable for use in tight spaces or on production lines with limited space. This compact size allows them to be easily integrated into existing production lines without requiring significant modifications or the addition of extra equipment.

In addition to their small size, Linear Feeders are also able to operate at high speeds, making them ideal for large volume production environments. This ability to work quickly allows them to keep up with the demands of modern production lines and helps to improve the overall efficiency and productivity of the manufacturing process.

Intricate Parts & Variations

One System, Multiple Parts

Linear Feeders can handle a wide range of parts, making them suitable for use in diverse production processes. This versatility allows them to be used in a variety of industries including medical device manufacturing, aerospace, and automotive.

Linear Feeders are designed to handle parts of different shapes, sizes, and materials. They can handle small, delicate parts as well as larger, more durable parts, making them suitable for use in a wide range of applications.

This ability to handle a diverse range of parts makes Linear Feeders an attractive choice for manufacturers who need to process a variety of different materials or who are looking for a single feeding solution that can be used across multiple production lines for low volume runners.

Minimize Downtime

Accurate & Reliable Parts Placement

Linear Feeders are highly accurate and reliable, ensuring parts are consistently orientated at the required cycle time. This helps minimize operational downtimes due to equipment failure. Accuracy is achieved using precise tolerances, high-quality components, and vigorous testing, to ensure parts are consistently presented in the correct orientation.

Another key advantage of linear feeders is their strong reliability. These feeders are designed to operate continuously for long periods of time and with minimal maintenance requirements. This means that manufacturers can rely on them to consistently deliver parts in the correct orientation and cycle time without the need for frequent repairs or downtime.

Frequently Asked Questions (FAQs) About Linear Feeders

-

A linear feeder is a type of vibratory feeding system designed to sort, orient, and transport parts along a straight path with precise, controlled motion. The linear feeder acts as the tooling, buffer, and transfer point, handing off the pre-oriented parts to the next stage of automation.

Linear feeders use large electromagnetic drives to create small, rapid vibrations along a track or rail. These vibrations gently and consistently move the parts forward in a uniform fashion. Specifically designed mechanical tooling and air jets are used to sort and orient the parts to a known orientation. A final mechanical or vision based “qualification” is then performed to ensure only the correct orientation is allowed to pass into storage. The storage track geometry is carefully designed to prevent tipping, flipping, or jamming, ensuring that parts are delivered to downstream equipment, such as pick-and-place robots, vision inspection systems, assembly stations, or packaging lines, in a consistent manner.

In addition to transporting parts, the storage track serves as a buffer zone, storing a queue of parts between the feeder and the point of use. This helps maintain a continuous flow of parts even if there are temporary slowdowns in the orientation tooling, which improves overall system efficiency and reduces downtime.

-

Linear feeders are best for achieving multiple lines of feed within a small footprint. Linear feeders can also be modular where different sizes or types of parts need to be fed, and change-out tooling is required. The feeding speed can also be increased by using a linear system because the tooling can be designed with a downslope angle. In a bowl feeder, the parts must always be going “uphill” to get from the bottom of the bowl to the top, limiting the speed.

Linear feeders are especially valuable in situations where:

- Space constraints limit equipment placement. Linear feeders have a slim footprint and can be mounted in tight spaces or routed around obstructions, freeing up valuable floor space around work cells.

- High feed rates are required. Linear feeders are more adept at supporting high feed rates across multiple lanes. It is not uncommon for a single linear feeding system to have 8-10 lines of feed. Typically, multiple bowl feeders would be required to achieve this, resulting in higher noise levels and floor space requirements.

- Gentle handling is important. Linear feeders provide smooth, controlled motion and minimal part-on-part contact. They are ideal for delicate or precision components that might be scratched, marred, or damaged by the tumbling motion inside a bowl. Linear feeders are also easily lined with non-marring plastics such as UHMW or acetal. These inserts will not peel or flake off like a typical urethane coating that is used in a bowl feeder in these applications.

In short, linear feeders offer higher performance in a smaller footprint than traditional bowl feeders, with lower noise emissions and gentler handling of parts.

-

VTR’s linear feeders are engineered for durability, precision, and long-term consistency. Our designs feature rugged construction, low-maintenance drives, and custom tooling to match your part geometry. We also build our linear feeders to integrate seamlessly with other automated systems, minimizing downtime and maximizing efficiency.

-

Linear feeders can handle a wide range of parts including plastic, rubber, metal, and composite materials. They are commonly used for components such as caps, connectors, fasteners, pins, electrical terminals, and other small to medium-sized parts. VTR customizes each feeder to ensure reliable performance based on your part’s weight, geometry, and surface characteristics. Part sizes range from 2mm to 100mm or larger in certain cases.

-

Feed rates vary depending on the part size, weight, and orientation requirements, but linear feeders typically deliver a range of 60-400 parts per minute (ppm). Higher speeds are possible with lightweight or simple geometry parts, especially when using multi-lane configurations.

-

Yes. VTR designs custom tracks and tooling to accommodate a wide variety of part geometries and sizes. For optimal performance and efficiency, linear feeders are typically dedicated to handling one specific part type or a closely related family of parts, which helps ensure smooth, reliable feeding without jams or misalignment. That said, linear feeders can be built to accommodate change out tooling that can be quickly swapped out when running different components on a line.

-

Linear feeders are compact and can be designed to accommodate your layout. They typically require only a narrow linear footprint and can be mounted on heavy duty tables or mounted directly to existing automation frames (size dependent).

-

Yes. VTR can design multi-lane linear feeders to increase throughput or feed multiple lines simultaneously. This approach increases overall feed rate while maintaining the same precision and consistency between lanes. Multiple lanes with lower feed rates per lane increases reliability compared to higher rates from a single line of feed.

-

VTR’s linear feeders are engineered from the ground up for seamless integration into automated production systems. Each feeder can be equipped with a variety of sensors to monitor part flow and ensure consistent supply to downstream equipment. These sensors can signal a PLC (Programmable Logic Controller) or robot to start, stop, or adjust speed based on real-time demand, preventing overfeeding or starvation of parts.

We can also incorporate escapements, part stops, and end-of-track controls that release individual parts to pick-and-place robots or vision inspection systems in a controlled manner. These modules are designed to synchronize perfectly with robotic cycles, allowing for precise timing and repeatable positioning.

VTR provides feeders with fully integrated controls and interface wiring that tie directly into your existing automation architecture. This plug-and-play approach minimizes integration effort, reduces commissioning time, and ensures reliable operation from day one.

-

Linear feeders can be built for a variety of environments, including cleanrooms, washdown areas, and industrial production lines. We customize materials, coatings, and sealing to meet your specific regulatory or environmental requirements. VTR specializes in designing linear feeding systems for customers in the medical device, pharmaceutical, automotive and packaging industries, while also supporting clients across virtually every sector where automated parts handling is required.

-

Linear feeders are typically quieter than bowl feeders, especially when properly mounted and isolated. VTR can incorporate noise-reducing materials, enclosures, and track coatings to further reduce sound levels if your application requires low-noise operation.

-

Maintenance is minimal, typically limited to occasional track cleaning and periodic inspection of springs, fasteners, and wear components. Over time, performance can degrade due to factors like worn tooling, buildup of debris, or misalignment from continuous vibration. VTR designs all feeders to be easy to access, adjust, and service to minimize downtime.

Our dedicated service team can also provide ongoing support, preventive maintenance, and repairs after installation to keep your system running at peak performance. To schedule maintenance or request support on your linear parts feeder, submit a service request or call us at 1-800-313-8655.

-

To provide an accurate quote, we typically require sample parts, part drawings, material specifications, and details about your desired feed rate and downstream equipment. Our team will evaluate your parts and propose a tailored feeding solution. You can submit a request for quotation on our website here.

-

Yes. Linear feeders are well-suited for high-speed, high-volume production environments. They are designed for continuous operation with large bulk storage or can even be integrated with automatic hopper loading systems. Linear feeders typically deliver between 60–300 parts per minute, though can be customized to reach 500-1000 ppm depending on the part.

-

Safety features can include interlocked guarding around moving components, lockout/tagout provisions, and sensors to prevent jams or overfeeding. VTR designs feeders to meet applicable safety standards and can incorporate custom safety features upon request.

-

All of VTR’s linear feeder tooling is CNC machined from CAD models to be fully reproducible lane to lane. No hand fabrication is used. We apply strict quality control, standardized manufacturing practices, and thorough testing to every feeder we produce. Each unit is custom built and tested with your parts to ensure reliable, repeatable performance before it leaves our facility.

Ready to review how a Linear Feeder could help your production needs?

Our Linear Feeders use vibratory technology to feed parts through a production line in a timed, reliable, and repeatable fashion, with the ability to add multiple lanes as needed.

Request Quote